Introduction of Falling Film Evaporator

1. Working principle :

Falling film evaporation is to add the material liquid from the upper tube box of the falling film evaporator heating chamber, distribute it evenly into each heat exchange tube through the liquid distribution and film forming device, and flow into a uniform film from top to bottom under the gravity and vacuum induction and air flow. During the flow process, the steam is heated and vaporized by the shell heating medium, and the generated steam and liquid phase enter the separation chamber of the evaporator together, the steam and liquid are fully separated, and the steam enters the condenser to condense (single-effect operation) or enters the next effect evaporator as the heating medium, so as to achieve multi-effect operation, and the liquid phase is discharged by the separation chamber. Can be widely used in medicine, food, chemical, light industry and other industries of water or organic solvent solution evaporation concentration, and can be widely used in the above industries of waste liquid treatment.

2. Application range:

Falling film evaporator is widely used in the evaporation and concentration of water or organic solvent solution in pharmaceutical, food, chemical, light industry and other industries, and can be widely used in the waste liquid treatment of the above industries. Especially suitable for heat sensitive materials.

3. Feature:

1) Can evaporate high concentration, high viscosity materials

2) High heat transfer coefficient.

3) Short residence time, not easy to cause material deterioration

4) Small liquid retention

5) Can be evaporated at low temperature

6) The whole process of the feed liquid does not form too much impact, avoiding the formation of foam

4. Structure:

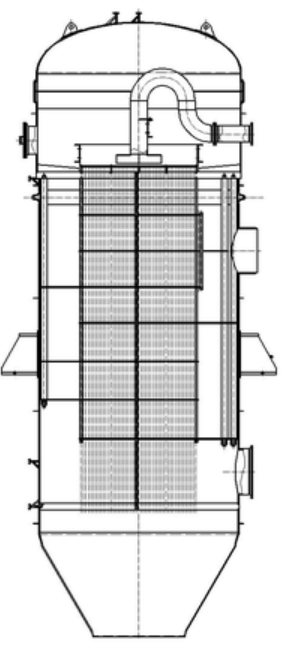

The falling film evaporator is a vertical shell and tube heat exchanger in form. The top of the evaporator is a liquid distributor, and the lower part is a heat exchange tube. The materials of the tube and shell processes are stainless steel and carbon steel respectively.

5. Component:

It is composed of evaporator (heat exchanger), separator, preheater, condenser, condensate tank, circulating pump and other parts.

1) Evaporator (heat exchanger) : normally tubular type, the main function: heating and evaporation of liquid materials

2) Separator: single-layer structure tank, the main function: to separate the secondary steam generated after heating from the concentrated liquid gas-liquid.

3) Preheater: horizontal tube type or plate type. Main function: pre-heating the liquid material entering the steam; The secondary steam is cooled so that it can be recycled.

4) Condenser: horizontal tube type or plate type. Main function: Condense the secondary steam so that it can be recycled.

5) Condensate tank: single-layer structure tank, main function: through the connection with the pump at the outlet, can realize the automatic discharge of condensate in the tank.

6. Parameter:

| Equipment name | falling film evaporator |

| Material | SS316/304 |

| Working effect | 1-5 effect |

| Evaporation capacity | 50-50000L/hr |

| Power | 1-100kw |

| Voltage | 380V/220V/60Hz/3P |

| Feeding solution | low concentration solution |

| Discharge concentration | 50-95% |

| Heating method | steam heating |

| Cooling method | chiller, cooling tower |