Introduction of DTB Crystallizer

1. Overview :

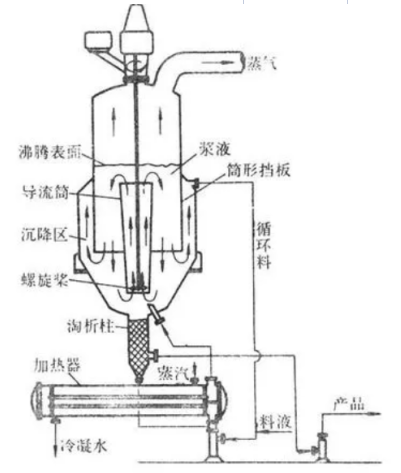

DTB(Draft Tube Baffled) crystallizer, is a typical intra-slurry circulating crystallizer. The circulation channel is formed because the inner flow tube is arranged in the mold, so that the crystal slurry has a good mixing condition, and only a very low pressure head is required to achieve a good internal circulation in the mold.

2. Working principle:

The temperature of the feed liquid inside the heat exchange tube of the heater increases from the steam outside the heat exchange tube. Under the action of the circulating pump, the material rises to the evaporation separator. As the static pressure of the material drops, the material evaporates, and the secondary steam generated by the DTB crystallizer overflows from the feed liquid. The substance is concentrated to produce supersaturation, which causes the crystal to grow and release supersaturated matter. It enters the forced circulation pump and enters the heat exchanger under the action of the circulation pump. The material circulates back and forth in the DTB crystallizer, continuously evaporates and crystallizes, so as to realize the separation between substances, achieve the purpose of purifying chemical substances and obtaining chemical products.

3. Main characteristics:

1) According to the characteristics of the material and the amount of evaporation, it can be designed as a single-effect or multi-effect evaporation device.

2) The unique design of crystallizer can meet the 0 process requirements of continuous feed and continuous discharge.

3) The whole process is evaporation under vacuum conditions, the temperature is low, and the evaporation speed is fast. The evaporation energy consumption is low, the evaporation concentration is high, so that the material liquid with high viscosity is easy to flow and evaporate, and it is not easy to scale.

4. Application scope:

DTB crystallizer is mainly used for evaporative crystallization of crystallized solution. Widely used in chemical industry, metal mine smelting, large steel pickling waste liquid, power plant wet desulfurization waste liquid treatment.

Applicable products are potassium chloride, iminodiacetonitrile, ammonium sulfate, ammonium chloride and so on.

5. Component:

DTB crystallizer is composed of heater, forced circulation pump, evaporation separator, setting device, condenser, various material pump, condensate pump, vacuum pump, operating platform, electrical instrument control cabinet, internal pipeline valve.

6. Technical parameter:

| Equipment name | DTB crystallizer |

| Material | SS316/304/2205 |

| Working effect | single/double effect |

| Evaporation capacity | 50-50000L/hr |

| Steam pressure | 0.4-0.8Mpa |

| Steam consumption | 100-1000kg/h |

| Feed concentration | according to feed material |

| Output products | crystal |

| Evaporation temperature | 45-90C |

| Cooling water volume | according to capacity |