MVR Falling Film Evaporator

1. Working principle :

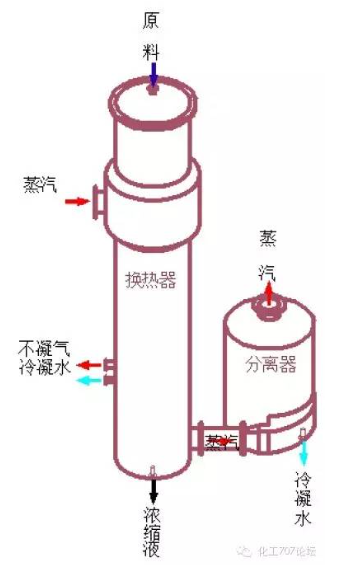

The raw material liquid is added from the upper tube box of the heat exchanger, and the material is distributed to each heat exchange tube through the liquid distributor, and a uniform liquid film is formed along the inner wall of the heat exchange tube. The liquid film in the tube is heated by the heating steam of the shell in the process of flowing down, and boils and evaporates while flowing down. To the bottom of the heat exchange tube material into concentrated liquid and secondary steam.

The concentrated liquid falls into the lower pipe box, and the secondary steam enters the gas-liquid separator. The liquid droplets entrained by the secondary steam in the gas-liquid separator are removed, and the pure secondary evaporation is transported from the separator to the compressor. The compressor compresses the secondary steam and transmits it as heating steam to the shell of the heat exchanger for the evaporator heat source. Achieve continuous evaporation process.

2. Application range:

Falling film evaporator is suitable for the pre-concentration process of MVR evaporation crystallization process, which can evaporate materials with large viscosity, especially for heat-sensitive materials.

3. Feature:

1) high heat transfer efficiency

2) Small footprint

3) the material stay time is short, not easy to cause material deterioration.

4) suitable for high viscosity materials.

4. Construction: