MVR Foced Circulation Evaporator

1. Working principle :

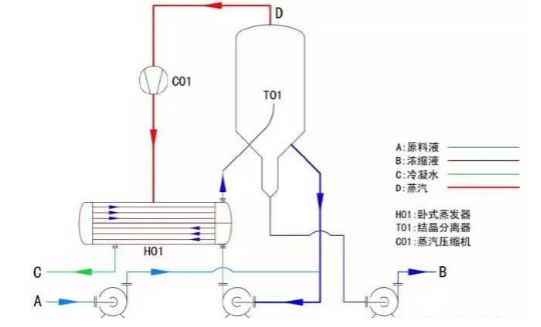

The forced circulation evaporator is composed of an evaporation separator, a heat exchanger and a forced circulation pump. The temperature of the material in the heat exchanger heat exchange tube is heated by the steam outside the heat exchange tube. Under the action of the circulating pump, the material rises to the evaporation separator. In the evaporation separator, the material evaporates because the static pressure of the material drops.

Evaporation produces secondary steam overflow from the material, the material is concentrated to produce supersaturation and crystal growth, the supersaturated material enters the forced circulation pump, enters the heat exchanger under the action of the circulation pump, and the material is continuously evaporated and concentrated or concentrated crystallization.

The slurry is exported from the circulation line by a discharge pump. The secondary steam in the evaporation separator is purified by the separation and demoaming device at the upper part of the evaporation separator and then transported to the compressor, where the compressor compresses the secondary steam and then transmits it to the shell of the heat exchanger as the evaporator to heat the steam, so as to realize the continuous evaporation of the heat energy cycle.

2. Application range:

It is suitable for the process of easy scaling, crystallization, evaporation concentration or evaporation crystallization of high viscosity materials.

3. Feature:

1) Low heat transfer coefficient

2) The heat exchange surface is not easy to form scale or crystallization.

4. Construction: