Fruit Juice Processing Line

1. Brief introduction :

Fruit juice production line mainly produces natural fruit juice, fruit juice drinks, fruit juice drinks with pulp, fruit juice refreshing drinks, concentrated fruit juice drinks, etc. The main ingredients of these beverages are different, but the basic principles and processes of production are roughly the same. Generally, fruit raw materials are manufactured by fruit juice production lines after pretreatment, juicing or extraction, clarification and filtration, homogenization, deoxidation, concentration, composition adjustment, packaging and sterilization. The juice production line is suitable for making all kinds of juice.

2. Application

The production line is suitable for the production and processing of apple, pomegranate, sea buckthorn, blueberry and other large concentrated juice.

3. Process flow

Cleaning - fruit detection - crushing - beating - juicing - filtration - concentration - blending - sterilization - aseptic storage - aseptic filling - set of labels - finished product packaging

4. Process discriptioin

(1) Selection of raw materials: The raw materials for making juice should be soft fruits with higher maturity, and the fermented spoiled and immature fruits should be removed.

(2) Cleaning: The cleaning of raw materials before juicing is an important measure to reduce pollution, and more attention should be paid to juicing with skin. Therefore, the silt and impurities on the peel must be washed away with running water. Rinse with water after the solution if necessary.

(3) Beating: The beater is used in the concentrated juice production line to beat, peel, wrap the pulp with a cloth to extract the juice, and the juice yield can reach more than 70%. Or pour the washed fruit into a press to extract the juice, then use a scraper filter to remove the skin, fruit seeds and some coarse fiber.

(4) Deployment: Dilute the juice after coarse filtration with water first. Then mix in proportion and stir until the sugar is completely melted.

(5) Filtration: The prepared juice is filtered and separated by centrifugal filter to remove the residual peel, seeds, part of the fiber, pulp and impurities

(6) Homogenization: The filtered juice is homogenized by the homogenizer, which can further break the fine pulp and maintain the uniform turbidity of the juice. The homogenizer pressure is 10~12 mpa.

(7) Sterilization and cooling: The concentrated juice is sterilized by high temperature sterilization and other methods, the sterilization temperature is 85℃, and the cooling is below 40℃.

(8) Filling and sealing: Heat the juice, fill it at no less than 85 ° C, and seal it quickly.

5. Component:

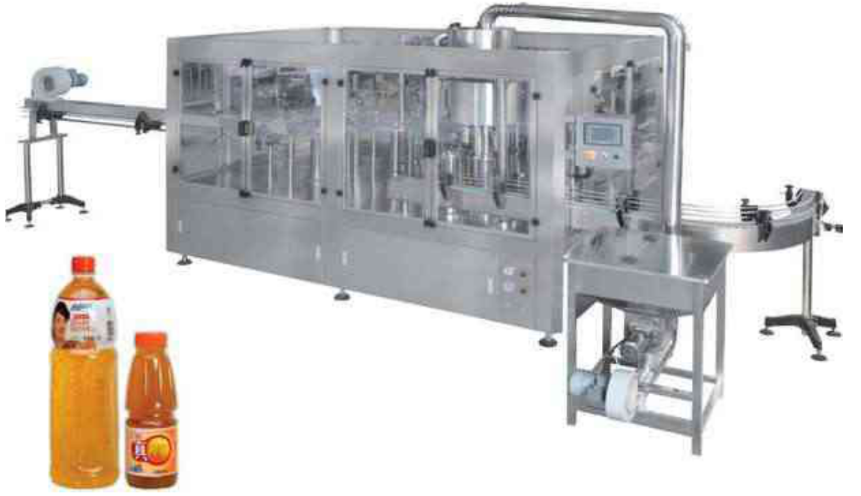

![]()

Conveyor,Cleaning machine,Fruit detection machine,Crusher,Juicer,Filter,Degassing device,Concentrator,Sterilization machine,Filling machine.