Introduction of Forced Circulation Crystallizer

1. Overview :

FC ( forced circulation) crystallizer is also called growth crystallizer. The crystallizing apparatus has the characteristics of simple structure and easy operation. The region where the crystals grow is at the lower end of the crystal separator. The bottom of the crystallizer is generally equipped with a crystal panning device.

2. Working principle:

The forced circulation evaporative crystallizer is a kind of continuous crystallizer with crystal slurry circulation.

During operation, the feed liquid is added from the lower part of the circulation pipe, mixed with the crystal slurry leaving the bottom of the crystallization chamber, and sent to the heating chamber by the pump. The crystal paste is heated in the heating chamber (usually 2 ~ 6 ° C), but no evaporation occurs. After the hot crystal slurry enters the crystallization chamber and boils, the solution reaches a susaturated state, so that part of the solute is deposited on the surface of the suspended grain, making the crystal grow. The crystal slurry as a product is discharged from the upper part of the circulation tube. The production capacity of forced circulation evaporation crystallizer is large, but the particle size distribution of the product is wide.

3. Main characteristics:

1) Growth crystallizer

2) Simple structure and easy operation

3) The particle size of the product is about 0.05 ~ 1mm

4. Application scope:

Forced circulation crystallizer is widely used in chemical industry, light industry, medicine and other industries, wastewater evaporation crystallization treatment.

5. Component:

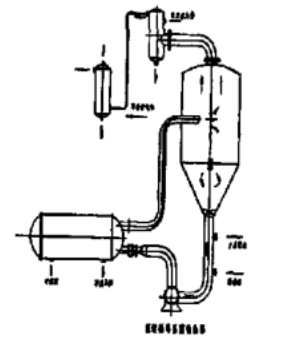

The forced circulation crystallizer is mainly composed of crystallization chamber, circulation tube, circulation pump, heat exchanger and so on. The crystallization chamber has a conical bottom. After the crystal slurry is discharged from the cone bottom, it is pumped through the heat exchanger through the axial flow circulation pipe. After being heated or cooled, it enters the crystallization chamber again, and so on. The slurry discharge outlet is located near the bottom of the cone of the crystallization chamber, while the feed port is at a lower position below the discharge port.

6. Technical parameter:

| Equipment name | forced circulation crystallizer |

| Material | SS316/304/2205 |

| Working effect | single/double/multiple effect |

| Evaporation capacity | 100-500000L/hr |

| Steam pressure | 0.4-0.8Mpa |

| Steam consumption | 100-1000kg/h |

| Feed concentration | according to feed material |

| Output products | slurry with crystal |

| Crystal size | 0.05-1mm |

| Equipment dimension | according to capacity |