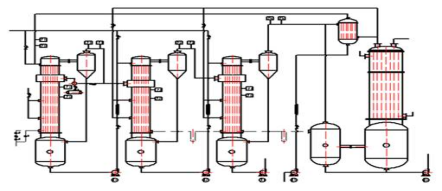

2000L per hour Three-effect falling film evaporator for isinglass concentration

Introduction

The three-effect falling film concentrator mainly adopts falling film evaporation concentrator process to vaporize and concentrate materials. The evaporation temperature of materials is low and the heating time is short, which is convenient to protect the color, flavor and nutrients of products. It is more suitable for the concentration of milk, juice, soy milk, tea, fermentation liquid, food additives, biological agents and other materials, especially for the vacuum concentration of heat-sensitive materials.

Working Principle

In the process of falling film evaporation, when there is sufficient heat flow intensity on the heating surface of the liquid or the wall temperature exceeds a certain value of the liquid temperature, an extremely thin liquid layer (retained heat boundary layer) will be generated between the liquid and the heating surface, thus forming the temperature difference. This very thin liquid layer (film) is heated phase transition, absorb latent heat and evaporation, so that the liquid in the tube does not have to reach saturation temperature, on the heating surface bubbles and boiling, then the superheat of the bubble exceeds the temperature difference of heat transfer from the film, so evaporation is completely carried out on the surface of the film, the boiling is called surface boiling.

Component

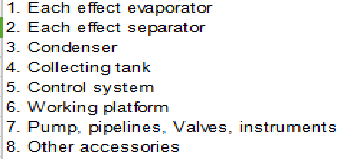

Parameter

| Equipment material | SS304/316 |

| Feed solution | low concentration solution |

| Feed temperature | normal temperature |

| Feed concentration | 5-30% |

| Discharge concentration | 50-90% |

| Evaporation capacity | 2000L/h or as request |